GDMS-PCN13

Gear and Diesel engine Monitoring System

Propulsion Condition Navy

Preamble

Damages to bearings can be caused by metal particles within the bearing clearance, low oil pressure, overheated oil, etc. The result of such malfunctions is a breaking oil film between the sliding parts.

As soon as the oil film is broken a thermo voltage occurs due to the friction between the different metallic alloys.

Functional description

The GDMS-PCN13 system is an online condition monitoring system which measures and analyzes the thermo voltage. The main parts of the system are the Slip Ring Transmitter, the Evaluator and the specially designed "Logger" software.

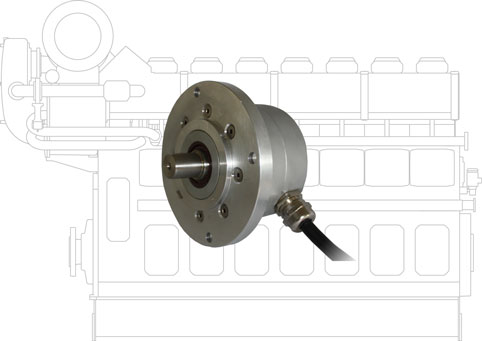

Slip Ring Transmitter (SRT)

The Slip Ring Transmitter (SRT) contains a special slip ring with redundant carbon brushes which receives the thermo voltage signal from the crankshaftengine system. The SRT is also equipped with an incremental encoder to bring the measured signal in relation to the rotation of the crankshaft.

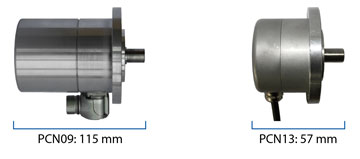

Comparison of the overall length of PCN09 and PCN13

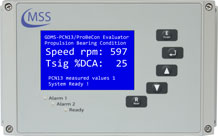

Evaluator

The Evaluator is designed to withstand the environment in the engine room. Its vibration resistance allows an installation near the engine without any special support. For installation on the engine, a special vibration damping feature is available.

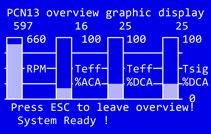

The Evaluator consists of a metallic case, a liquid crystal display (LCD), three LEDs indicating the system status and five membrane buttons for user interaction. A powerful processor inside the Evaluator analyzes the measured data continously, displays the data on the LCD and triggers the alarm relais in case of thermo voltage. The bargraph display makes recognizing the current measurement data easy.

Logger Software

The Logger software is capable of receiving measurement data of up to six connected PCN13 systems simultaneously. It is used to display and store the data for later analyzation.

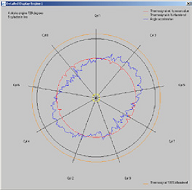

The Logger software also supports the localization of the damage inside your engine. This is done by additionally using the cylinder firing sequence of the engine and the incremental encoder of the SRT. The result of the different information is the "Polar Diagram" of the Logger software. It shows the measured thermo voltage over the engine rotation. The diagram also contains the firing sequence of the engine so the operator is able to recognize easily which bearing is affected.

GDMS-PCN13 Benefits

- Fully redesigned sensor, compatible to existing installations

- Shorter overall length of sensor and mounting adapter (compared to a PCN09 installation)

- Easy installation

- Online and continuous monitoring

- Optimization of the availabilty and reliabilty of the engine

- Early and reliable detection of bearing anomalies

- No unnecessary bearing inspections

- Minimizing engine maintenance and service costs

- Maintenance free

Technical Data

| Power-Supply | 24V DC +30%/-25% |

|---|---|

| Operating Current | max. 1.5A |

| Alarm level | adjustable in 5 steps |

| Outputs | 3 isolated relay contacts:

|

| Data interface |

|

| Ambient temperature | 0 - 70°C for Evaluator and SRT |