GDMS-OMDN09®

Gear and Diesel engine Monitoring System

Oil Mist Detection System Navy

Preamble

Oil mist inside an engine is produced when lubricants or fuel come in contact with hot surfaces. Damaged bearings can also lead to oil mist due to friction which induces heat. This oil mist becomes high ignitable at a concentration of 50mg/l or higher. An explosion can cause large scale engine damages and in a worst case the loss of human lives.

Functional description

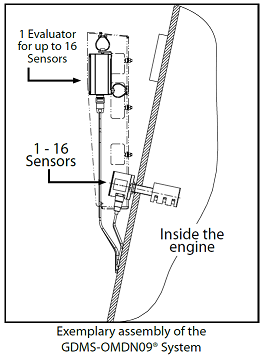

The GDMS-OMDN09® system is an oil mist detection system without the disadvantages of older OMD systems. It is a pipe-free system, with sensors mounted directly at the engine wall which allows a quick and exact measuring of the produced oil mist in each compartment.

The measured data of each sensor are sent via a redundant serial bus to the Evaluator which processes and displays the data of the whole system. Up to 16 sensors can be connected to one Evaluator. For the case of an alarm, the Evaluator is equipped with two independent relais, so i.e. the shutdown of the engine can be initiated to prevent further damage.

Additionally, the measured data can be sent from the Evaluator to a PC with a specially designed software and/or to a GDMS-OMDN09® Remote Monitoring Unit.

The PC software is able to display, store and review the measured data.

The Remote Monitoring Unit is able to display the measured data like the Evaluator. It has also the capability to reset an alarm.

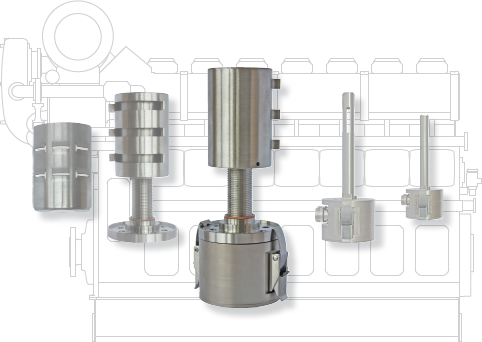

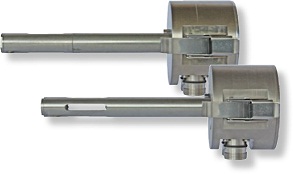

Sensor

The sensor measures the oil mist directly where it is generated, inside the engine. It is very sensitive, so it can even measure smallest amounts of oil mist. Without any moving parts and without piping, the installation is very easy and almost no maintenance is needed. Sensors are available for Gas and Diesel engines.

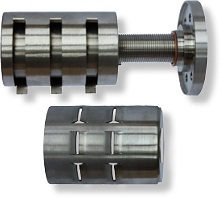

SOPS and Diffusor

The Splash Oil Protection System (SOPS) protects the measuring section against oil splashing inside the engine. With its multiple chamber design only oil mist can get to the measuring section.

In cases of high splash oil concentrations, the diffusor can be mounted onto the SOPS for even better splash oil protection.

Evaluator

The Evaluator is designed to withstand the environment in the engine room. Its vibration resistance allows an installation near the engine without any special support. For installation on the engine, a special vibration damping feature is available.

The Evaluator consists of a metallic case, a liquid crystal display (LCD), three LEDs indicating the system status and five membrane buttons for user interaction. A powerful processor inside the Evaluator analyzes the measured data continously, displays the data on the LCD and triggers the alarm relais in case of oil mist. The bargraph display makes compartment localization easy.

GDMS-OMDN09® Benefits

- Easy installation due to simple electric cabeling

- Pipe-less and suction free oil mist detection system

- Online and continuous monitoring

- Features the display of the oil mist concentration in mg/l

- Measurement of the temperature in each compartment

- Self-redundant measurement system

- Maintenance free optical sensor system protected against splash oil contamination

- No moving parts

- GDMS-OMDN09® Sensor replacement is possible at any time

- Minimizing engine maintenance and service costs

Technical Data

| Power-Supply | 24V DC +30%/-25% |

|---|---|

| Operating Current | max. 1.5A |

| Alarm level | adjustable in 10 steps (0.2 - 10mg/l) |

| Outputs | 3 isolated relay contacts:

|

| Data interface |

|

| Ambient temperature | 0 - 70°C for Evaluator 0 - 85°C for Sensor Electronics -10 - 120°C for Sensor Measuring Section |